More and more companies focus on implementing in-house tailored digital technologies with the help of custom hardware development services.

Instead of endlessly adapting readymade products offered by available tech vendors, you can get a turnkey solution that will closely meet individual business requirements and scale almost indefinitely, eliminating the necessity of constant costly upgrades.

We offer professional hardware development engineer services for modern electronics, as well as design and tracing of printed circuit boards. Our hardware development company works with different processor architectures, interfaces, and memory types, implementing the latest technologies.

Hardware development is a complex effort that includes the creation and optimization of electronics and mechanical system elements that perform various computational processes. The connection between these elements and objects is usually realized through a hardware interface.

Hardware development is usually carried out through the following stages:

- schematic development of hardware elements;

- hardware elements’ implementation (in the form of a printed circuit board or their combination);

- hardware elements testing in the laboratory environment;

- system integration;

- hardware testing in the field conditions.

By the way, the first stage of the hardware development process is the most important. After all, the correct hardware design not only reduces the project budget but also prevents a number of potential breakdowns and downtimes.

Let’s figure out in which cases hardware development services are a top priority.

- First of all, when the market devices are either too expensive or don’t contain the necessary features (and to implement your plan, you will have to pay extra for hardware with a bunch of redundant functionality)

- The second case is when you want to implement a unique startup – launch a solution based on a technology that has never been used in your niche or has been neglected. Custom hardware comes to the rescue when you simply can’t find readymade equipment that would satisfy your needs.

- Lastly, the third typical case is when the embedded hardware solutions available on the market don’t meet the requirements for operating conditions. For example, they are not energy-efficient enough or unable to withstand certain climatic conditions. In this case, we will use simple electronic systems that can be put in heat-resistant and water-repellent housings to fully protect them in an unfavorable environment.

When implementing hardware development services, companies often face typical issues:

- Design changes

The integrated circuits design is created at the very first stages of the project development cycle. If the client requirements suddenly change, additional costs are provoked – both financial and time resources required for the updated design of new printed circuit boards. - Non-compliance with quality standards

Non-compliance with generally accepted quality standards for embedded hardware equipment (for instance, ISO) can cause downtime as well as serious system damage. That’s why it is very important to make sure that the specialists you hire are able to comply with all the common standards before cooperation. - Unprofitable readymade solutions.

No hardware development company can guarantee you that the hardware they create will turn out to be the most budget-friendly option available. That’s why it’s better to conduct thorough market research for the existing solution prices before contacting specialists.

Fortunately, our specialists have a high level of expertise to avoid all of the above problems and provide you with a smoothly working, top quality product at the lowest cost.

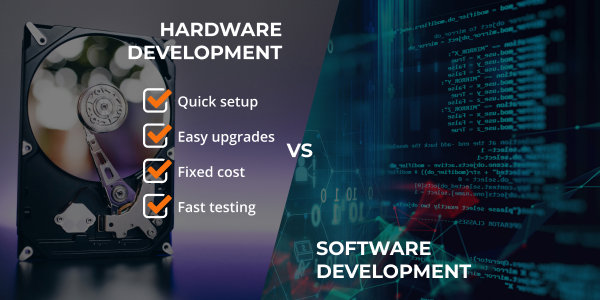

The debate about which is more important – software or hardware, is quite regular.

There is one compelling argument that software is much more important than hardware – no matter how powerful a smartphone, laptop, or computer is, it won’t be able to run at its full capacity if there is no proper software to manage it. It’s even worse if the software is poorly designed and difficult to use.

Alternatively, try making your old computer or outdated smartphone work with the latest software. Do you notice that it is not possible to achieve normal performance due to a lack of firmware power? That is exactly why both well-made software and hardware are equally important.

The development of both software and hardware is associated with the implementation of special algorithms that set off the performance of electronic or electromechanical devices. But software is more suitable for algorithmically complex projects with a high computational load and need for data storage. In turn, the hardware is usually used in automation systems where a more limited range of tasks must be performed.

- Quick setup.

Integrated circuits almost don’t need local adaptation – developers usually implement all configurations at the design stage. Software is a completely different case – it is often created in an extremely universal format and requires constant administration. - Easy upgrades.

If you wish to upgrade a system based on custom hardware, you just need to replace several printed circuit boards. In the case of software upgrades, developers may have to redo thousands of code lines and retest the final software product. This takes a lot of time and money. - Fixed cost.

Hardware development cost is almost always fixed, whereas software development cost can rise unexpectedly even during the final project stages. - Fast testing.

Software undergoes dozens of repetitive testing procedures and is never guaranteed to come out completely free of bugs (errors that go against product specifications). In turn, hardware testing implies a limited list of manipulations that don’t require much time and separate QA team participation. In particular, for printed circuit boards and integrated circuits, we perform signal integrity analysis (SI), electromagnetic compatibility analysis (EC), power integrity analysis (PI), and JTAG testing.